Delving into the world of Formula 1, the pinnacle of automotive engineering and speed, brings to light the sheer complexity and expense involved in crafting these high-performance machines.

Each component of a F1 car is a marvel of technology and design, from the aerodynamically sculpted chassis to the intricate power units that thunder down the racetrack. The cost of an F1 car is staggering, reflecting the extensive research, cutting-edge materials, and labor required to assemble a single F1 vehicle.

Teams invest substantially to stay competitive, adhering to stringent regulations while pushing the envelope of innovation. The annual budget cap introduced to maintain a level playing field does not include expenditures like driver salaries, marketing, and the costliest elements of their operations.

With the constant evolution of F1 regulations, teams must continuously invest in research and development, adapt their cars for performance gains, and ensure compliance with the latest safety and performance standards. Meanwhile, the need for regular maintenance and replacement parts during the season further contributes to the high running costs.

Key Takeaways

- F1 cars exemplify advanced engineering and are costly to develop and build.

- Team budgets are significant, managing production, performance, and compliance costs.

- Regulations influence expenditures and strategies in pursuit of technological advantages.

Overview of F1 Car Costs

Formula 1 cars are marvels of technology and engineering, where every component is optimized for speed and performance. The cost of these vehicles is reflective of their cutting-edge features and the extensive research and development required to stay competitive.

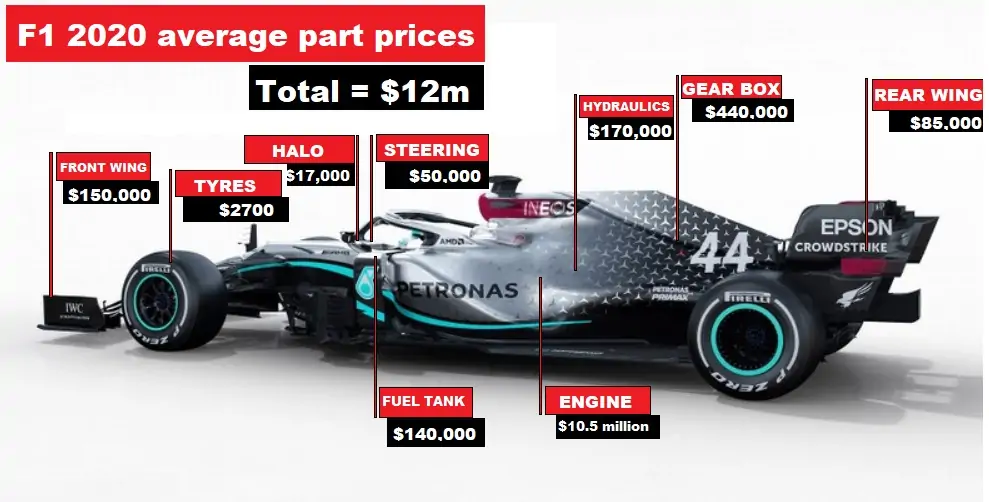

Components and Materials

Chassis: The core of the F1 car, typically made of carbon fiber, plays a crucial role in performance and safety. The cost of the chassis and bodywork involves significant investment due to the advanced materials and labor involved.

Engine: An F1 engine price ranges from $12 million to $15 million. It’s a hybrid power unit with complex components, contributing significantly to the car’s overall cost.

Gearbox and Hydraulics: The gearbox, together with the hydraulic system, ensures the smooth transmission of power. These components, though less costly than the engine, still represent a considerable expense.

Fuel Tank: Safely housing the fuel, the tank is constructed to withstand crashes and is an essential, yet expensive, part of the car.

Aerodynamics: Wings and other aerodynamic elements account for a portion of the expenses. These parts are meticulously crafted to provide downforce and stability.

Steering Wheels and Electronics: F1 steering wheels are highly sophisticated and can cost up to $50,000 each. They feature intricate electronics and control systems.

Tyres: While teams do not purchase tyres, as they are provided by the sole supplier, this is still a recurring expense throughout the season due to the number of sets used.

Brake Discs: Carbon brakes are optimized for performance and safety, each disc costing a few thousand dollars.

| Component | Approximate Cost |

|---|---|

| Chassis and bodywork | Custom |

| Engine | $12-15 million |

| Gearbox and Hydraulics | Custom |

| Fuel Tank | Custom |

| Wings | $200,000 |

| Steering Wheel | $50,000 |

| Brake Discs | Few thousand dollars per disc |

Design and Development

Research and Development: A substantial part of a Formula 1 car’s costs stems from design and development. Resources allocated to R&D influence the success of the vehicle on the track.

Budget: With budget caps, teams must strategically distribute funds across various departments, including aerodynamics and materials research, to gain a competitive edge while adhering to financial regulations.

Overall, the price tag associated with a Formula 1 car is not just about the sum of its parts but also reflects the technological advancement and continuous development necessary in the high-stakes world of Formula 1 racing.

Team Expenditures

The financial realm of Formula 1 teams involves a harmonious yet costly blend of driver talent and technological prowess, all under the watchful eye of the F1 budget cap.

Driver Salaries

In the world of Formula 1, a team’s expenditure is significantly impacted by the salaries of its drivers. Top-tier drivers, including world champions, command high remuneration packages. For instance, a driver like Valtteri Bottas, who has race-winning experience, can negotiate a substantial salary that reflects their market value within the sport. This expense can vary widely from one team to another, but it is encapsulated within the budget cap that regulates team spending to ensure a level playing field.

Engineering and Support Staff

Beyond the cockpit, the payroll continues to burgeon with the inclusion of engineering and support staff. F1 teams invest heavily in an army of the finest minds in motorsport to stay competitive. This encompasses various specialists in the fields of aerodynamics, electronics, and material science. Alongside the core engineering team, there is substantial support staff, all dedicated to flawless race execution and continuous vehicle development. Despite the budget cap aiming to cap the arms race of spending, teams judiciously allocate resources to retain and attract the best talent in these critical areas.

Manufacturing and Production

The production of a Formula 1 car is an intricate process, involving advanced factory operations and the selection of high-quality materials for construction. It adheres to strict budgetary constraints known as the cost cap, while incorporating sophisticated hybrid components and software.

Factory Operations

Factory operations in Formula 1 involve highly specialized environments where both technology and human expertise play crucial roles. The process of developing a Formula 1 car begins with the design and engineering phase, requiring state-of-the-art software to model performance and aerodynamics. Teams employ precision manufacturing techniques to create the numerous parts that a car consists of. With the introduction of the cost cap, currently set at $140 million, teams must strategically allocate their budgets to cover all facets of production while maintaining a high level of competitiveness.

Materials and Construction

The construction of a Formula 1 car utilizes materials at the vanguard of technology such as carbon fibre, known for its strength and lightness. This material is dominant in the chassis construction, contributing to the car’s safety and aerodynamics. The gearbox, a unit that can cost up to roughly $350,000, is crucial for reliability and is meticulously manufactured to withstand the stresses of racing. Components like wheels and rims are also subject to stringent production standards due to their impact on performance and safety. The manufacturing process of these hybrid components demands precision to ensure they interact seamlessly with the rest of the car’s systems.

Performance and Testing

The pursuit of speed and reliability in Formula 1 hinges on rigorous performance testing, leveraging advanced technology to enhance aerodynamics and track operation capabilities.

Aerodynamics Testing

F1 teams utilize wind tunnel testing and computational fluid dynamics to meticulously examine the aerodynamic properties of their cars. In these controlled environments, engineers collect data to shape components such as the set of wings to maximize downforce and minimize drag. The objective is to achieve the highest possible speeds while maintaining stability—crucial factors when cars can exceed 300 kph (186 mph).

- Wind Tunnel Testing: Scaled models of F1 cars are subjected to powerful air streams to simulate real-world conditions.

- Technology in Use: Teams feed the data into simulations to predict how tweaks to design impact performance.

Track Testing and Simulation

Track testing is an essential phase where the car is put through its paces in a real-world scenario to gather performance data. Teams evaluate everything from the engine’s performance to the durability of the gearbox. Testing can highlight any potential weakness that might lead to crashes or failures during a race.

- Simulation: Advanced software predicts car behavior on different circuits and conditions.

- In-Circuit Testing: Professional drivers test the cars, pushing them to the limits of their speed and handling capabilities.

These sections of testing ensure that an F1 car’s performance is optimized before it graces the track on race day.

Regulation Compliance

Formula 1 teams must adhere to strict financial regulations set by the FIA to ensure fair competition and maintain the sport’s sustainability. Compliance with these regulations involves not only respecting the cost cap but also integrating safety and sustainability measures into their operations.

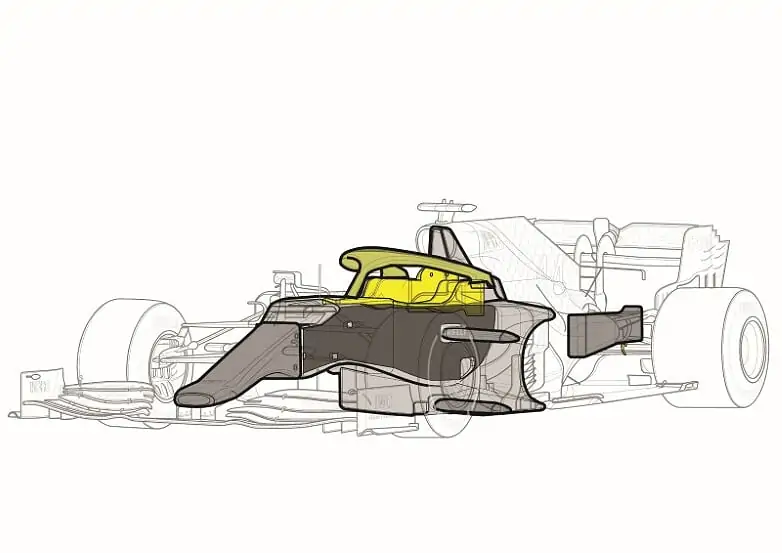

Safety Features

The FIA has established rigorous safety standards to protect drivers, crew, and spectators. One significant safety feature is the halo system, a titanium structure that forms a protective ring around the driver’s head. It has been mandatory since 2018 and is credited with saving lives in high-impact collisions. Teams must incorporate this safety feature without exceeding the cost cap.

In addition to the halo, F1 cars utilize advanced ground effect aerodynamics, designed to enhance downforce safely and efficiently. Despite being a performance component, it must comply with both the budget cap and safety regulations that the FIA enforces. Teams are challenged to optimize their designs within these financial and safety constraints.

Sustainability Measures

The FIA has also introduced measures to promote sustainability in Formula 1. Teams are required to use V6 hybrid engines, which are more fuel-efficient and have a lower carbon footprint than previous engines. These power units are integrated with the Motor Generator Unit – Heat (MGU-H) and Motor Generator Unit – Kinetic (MGU-K), which recover energy that would otherwise be wasted.

The batteries employed in these hybrid systems must meet FIA standards for safety and performance, ensuring they can withstand the rigors of racing. As with all aspects of the car, their development and usage fall under the fiscal oversight of the cost cap, promoting responsible financial stewardship alongside technological innovation.

Replacement and Maintenance

Maintaining a Formula 1 car is a meticulous and continuous process. Each component from the engine to the tires requires regular inspection and replacement to ensure peak performance and safety during races.

Regular Component Replacement

Formula 1 teams must regularly replace various components of the racing car to adhere to performance and safety regulations. Gearboxes, for instance, are subjected to extreme stress due to the high speeds and quick shifts seen in F1 racing. These gearboxes typically last for four to six races before requiring replacement.

- Tyres: Each F1 car has a limited number of tyre sets available for a race weekend, which includes practices, qualifying, and the race itself. Tyres are strategically chosen and replaced to match the race strategy and track conditions.

- Brake Discs: Made from carbon, they are designed for maximum deceleration from high speeds and must be replaced frequently due to the wear from the intense heat and pressure they endure.

- Steering Wheel: While not as frequently replaced as tyres or brake discs, the steering wheel is an essential and highly sophisticated component that teams will regularly maintain and occasionally replace to ensure functionality.

Repair After Wear and Damage

After each race event, teams thoroughly inspect the race car for wear and damage, which can often require extensive repairs.

- Maintenance Checks: Post-race, each car undergoes rigorous checks. These maintenance activities are crucial for identifying issues that may not be immediately apparent, such as micro-cracks or stressed parts.

- Crashes: In the event of crashes, the damage incurred can vary significantly. Teams are often faced with the extensive task of repairing or replacing numerous parts — from the chassis to the aerodynamic elements — which can be cost-intensive and time-consuming.

Race car maintenance and repairs are an essential aspect of Formula 1 racing, requiring teams to have the utmost precision and care to ensure their machines are up to the sport’s demanding standards.

Associated F1 Team Costs

Formula 1 teams incur significant expenses beyond the construction and development of a race car. Managing a team involves costs related to transport, marketing, and sponsorship activities which are critical for ensuring a team’s presence and competitive performance in the sport.

Transport and Logistics

The intricacies of global race schedules require teams to have a meticulous logistics operation. F1 teams spend millions annually to transport cars, equipment, and personnel. Red Bull, for instance, orchestrates the movement of its fleet to over 20 locations worldwide within a single season. This represents a major cost area that can exceed $10 million, depending on the number of races and their geographic dispersion.

Marketing and Merchandising

Merchandising renders a tangible connection between teams like Ferrari and their fans, promoting brand loyalty. It encompasses production and distribution of branded apparel and accessories. Marketing efforts, on the other hand, aim to amplify a team’s presence through campaigns and promotions. Together, these areas can demand a portion of the budget that rivals some small teams’ entire spending.

Sponsorship and Brand Partnerships

Teams such as Mercedes and Ferrari leverage their brand prestige to form lucrative partnerships. In return for sponsorship, brands receive global visibility at races and through broadcasting. Securing a title sponsor can significantly subsidize a team’s expenditure, with deals potentially reaching upwards of $100 million. Smaller teams, however, might rely on a multitude of partnerships to compile a comparable budget.

Revenue and Expenditure Overview

The financial aspects of Formula 1 include both significant revenues and expenditures. Teams generate income from various sources, including sponsorships, merchandise sales, and prize money. A notable avenue for revenue can also come from auctioning show cars or vehicles historically significant, such as those driven by legendary drivers like Juan Manuel Fangio. These auctioned vehicles may not only represent a storied past but also embody the technological prowess akin to a hypercar.

In terms of expenditures, the cost of designing, building, and maintaining an F1 car is substantial. Components such as the gearbox and wings represent high-value investments due to their complexity and the technological advancements they embody.

Exemplary Costs:

- Gearbox: Approximately $350,000 due to advanced paddle-shift systems.

- Brake System: A full system may incur costs of tens of thousands of dollars, with individual calipers priced around $5,600 each.

Expenditure Caps:

Starting in 2021, cost caps were introduced to encourage better financial sustainability within the sport. Initially set at $145 million, the cap decreases over time, aimed at $135 million from 2023.

Teams often sell decommissioned cars, typically those not deemed as collectibles, as show cars. These retired F1 machines are devoid of cutting-edge technology to comply with the regulations and for intellectual property protection. Nevertheless, they remain an enticing purchase for enthusiasts searching for a tangible piece of F1 glamour, frequently sold through specialized platforms.

Amidst growing costs and revenue streams, F1 continues its evolution, striving to balance the books while maintaining the unmatched spectacle of top-tier motorsport.

Frequently Asked Questions

The construction and maintenance of Formula 1 cars are a marvel of both engineering and finance. Costs can vary widely depending on the team’s strategies and performance goals, eliciting a range of intriguing questions.

What is the price range for building an F1 car?

The cost to build a Formula 1 car can range from $12 million to $15.9 million. This includes the price for design, development, construction, and testing, but variances occur based on the team and the specific components used.

How much does the top performing F1 team’s car cost?

Top performing Formula 1 teams can invest upwards of $400 million on total racing operations per season, which includes but isn’t limited to, the car’s construction, development, and performance enhancements.

What is the cost of a Formula 1 car for a single race?

For a single race, a Formula 1 car’s cost is not usually calculated, as expenses are inherently part of a season’s budget. However, cost elements such as repairs, upgrades, tire sets, and engine parts can collectively amount to several million dollars over one race weekend.

Can you purchase a used Formula 1 car, and if so, at what price?

Yes, a used Formula 1 car can be purchased, often at prices starting around $119,300. The exact cost varies based on the car’s condition, historical value, and whether it’s a complete vehicle or stripped of competitive components.

What is the financial comparison between a NASCAR and a Formula 1 car?

A Formula 1 car is significantly more expensive than a NASCAR vehicle. The cost of an F1 car, without factoring in research and development, can be over ten times more than the price of constructing a competitive NASCAR, which usually falls between $0.5 to $2 million.

How are the costs distributed in the creation of a Formula 1 race car?

The costs for creating a Formula 1 car are distributed across several areas: chassis construction, aerodynamics testing, engine development, and the assembly of numerous components such as tires, brakes, and advanced electronics. Each team has its own financial strategy to allocate spending effectively among these areas.